Heat In Relation To Configuration

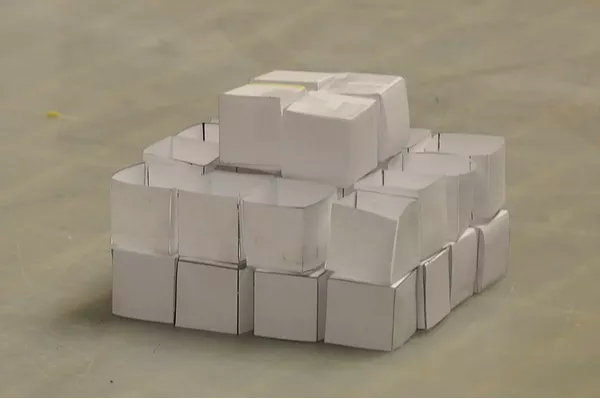

Prototype

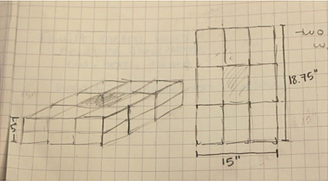

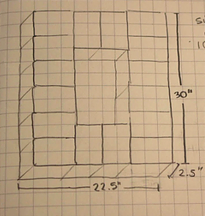

A quick prototype of the idea of varying the various configurations.

The design problem is to discover if certain room configurations will affect the heating activity of each individual room. As a group, we danced around the idea of basing our project on Kinetic structures. We were curious about the mechanics of movable buildings, how the shapes and materials affect the structure and how it responds to human needs. As we narrowed down on certain kinetic features, our top two were:

- A wedding cake style skyscraper that “collapses” downwards and fits into one another, effectively changing the volume to surface area ratio.

- A building that imitates the "15 puzzle”.

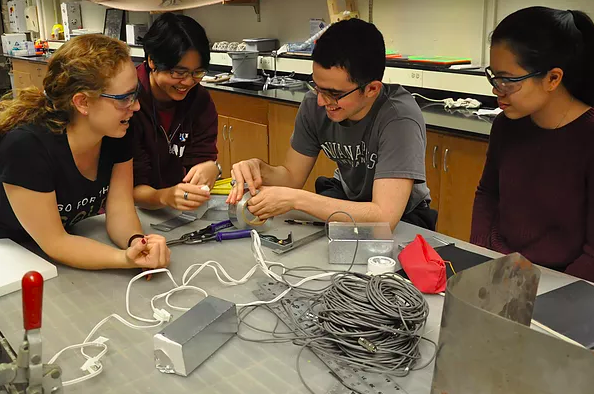

Model Box

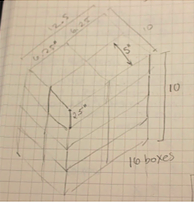

The discussion of what shape the box should be to accommodate the heat source and the temperature probe.

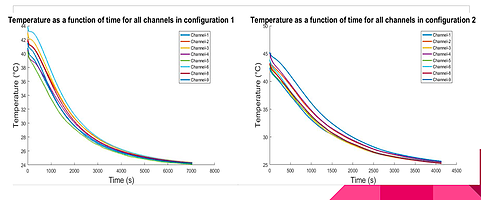

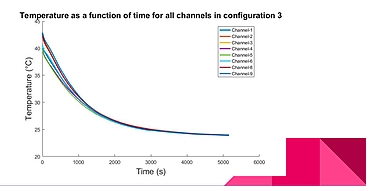

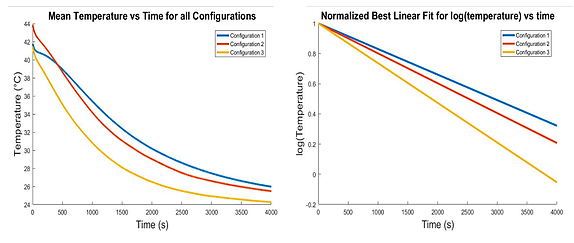

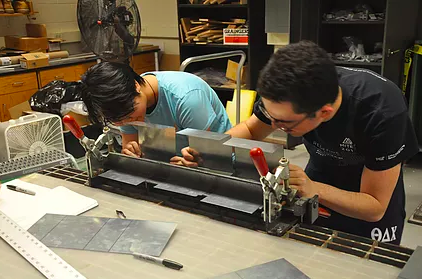

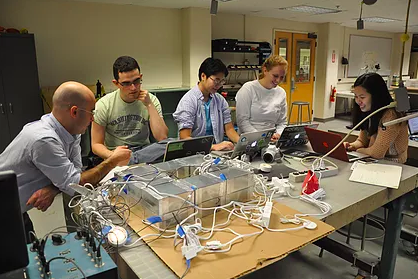

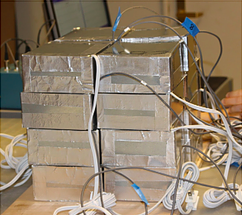

Deciding to go with the latter experiment (based on heater bees who raises the temperature of the colony), we ordered two packs of Canarm Under Cabinet Puck-Light with 6 in each pack in addition to 6 used ones as well as 3 sheets of .015" Thick Galvanized Low-Carbon Steel, 24" x 48”. The puck-light will serve as our heat source which can reach 60 degrees celsius in a matter of minutes. Our experiment design is to strategically place our limited 10 temperature probes in 16 boxes (keeping the configuration symmetry in mind) and raise the temperature to 60 degrees celsius and then shut off the heat source to observe how the temperature decays over time. Our boxes will imitate two recycled shipping containers (used as rooms in Amsterdam) side-by-side due to the restraint from the bending press which accommodates bending a box with dimensions of at least 2.5 inches. Therefore, we scaled the dimension ratios of the Amsterdam side-by-side shipping containers (1:2:2.5) by 2.5 making our box dimensions, 2.5”x5”x6.25”. The cost of the experiment totaled $174.05 from the lights and the sheet metal.

For each box, we separated into two sections, one is the body which consists of four sides and the other section is the caps with which to seal the box. We used metallic tape to close any gaps between the body and the caps as well as closing off the opened side of the body. We also metallically taped foam on the corners which we cut out in order to make space for the wires that will be coming out of the box due to the temperature probes as well as the heat source.

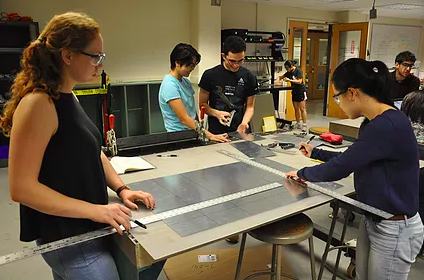

Measuring the Steel Sheets

Shearing the Sheet Metal Part 1

Shearing the Sheet Metal Part 2

Inputting heat sources and temperature probes

Bending the Sheet Metal

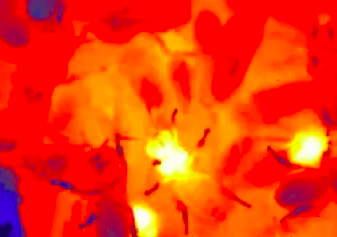

Analyzing the data from the Temperature probes

Experimental Implementation

#1: Four Story

#2: Two Story Courtyard

#3: Single Story Courtyard

Design Process: Concept Drawings

#1: Four Story

#2: Two Story Courtyard

#3: Single Story Courtyard

Results and Data Analysis

-

Different heat decay rates for different surface area-to-volume ratios:

Configurations 1 < 2 < 3 (slowest to fastest) - Hypothesis proven true: A more compact configuration loses heat more slowly